When carrying out work on the refinement of household plots, many owners opt for the construction of an artificial reservoir. This part of landscape design not only adds a “twist”, but also positively affects the psycho-emotional state of a person. The main objective of such an object is the desire to give it the appearance characteristic of natural origin, for which they use a special waterproofing material, which is laid at the bottom of the pond.

How to lay the bottom of the pond

Despite the wide selection, there are a few basic materials that are most often used to create ponds to cover the bottom. Each of them has its own characteristics, as well as individual styling technology.

In addition, there are general recommendations for choosing a waterproofing:

- with a pond depth of less than 80 cm, as well as a common small area, the bottom can be covered with a plastic film, with a thickness of about 0.5 mm;

- if the depth reaches 1.5 m, and the perimeter of the pond itself is about 3 m in length, a PVC film with a thickness of about 1 mm will be required;

- with greater depth and volume of water, the thickness of the waterproofing layer should be at least 2 mm.

Immediately before covering the pond with a waterproofing membrane, regardless of the material chosen, it is necessary to carry out preparatory work:

- Carefully align the bottom of the future pond, excluding swings.

- Form a mound of sand with a layer of 10 cm. Such a pillow will help to avoid further breakthrough of the insulating material during heaving of the lower layers of the soil.

- Further, the bottom is covered with a layer of geotextile, the density of which should not be less than 300 g / m² - it will act as a membrane protection against tearing due to the sprouting of tree roots or digging with moles, and will also help strengthen the coastline. At the same time, geotextile strips should be laid with an overlap of 20 cm and fixed with tape. Such material additionally serves as a heat insulator.

In addition to specialized materials, many summer residents use improvised means as a waterproofing agent, such as fine clean sand, non-woven materials and even banners.Important! Also, when choosing a membrane, it is required to take into account the load of the reservoir, i.e. the presence of fountains, waterfalls, the possibility of swimming in it, etc. (the higher the load, the thicker the insulator layer should be).

Video: Covering the bottom of a decorative pond

Butyl rubber

- It is a new generation of synthetic material, also known as rubber based EPDM membrane. It is characterized by a number of advantages:

- high strength, practically preventing breaks and punctures;

- ease of installation;

- resistance to negative environmental influences;

- simplicity of the repair procedure of individual sections;

- safety for nature and living organisms;

- the ability to apply to almost any surface;

- web width, which can reach 60 m;

- the presence of an extensive range of components (including those that make the sections on which pumps and other equipment connected more durable);

- long service life, which can reach 50 years.

Technical flaws in this material have not been identified, however, there is one minus - its high cost. However, given the long life, we can talk about the ultimate savings.

Technical flaws in this material have not been identified, however, there is one minus - its high cost. However, given the long life, we can talk about the ultimate savings.

As the butyl rubber rubber itself, the technology of its installation is progressive and does not require special skills:

- Liquid rubber is sprayed on top of the prepared geotextile.

- When sprayed, the insulating material completely penetrates the geotextile layer, forming a substrate.

The result of laying will be a monolithic membrane, devoid of seams, which means that it completely eliminates leakage. In the future, it remains only to decorate the bottom at its discretion.Did you know? Since water has a beneficial effect on the emotional state of a person, it is necessary to place a reservoir on the site so that it is clearly visible from the recreation area.

Bentomat

- Clay-based geosynthetic bentonite mats are distinguished by the following advantages:

- profitability of the material and the ability to use it in various fields;

- long term of operation;

- high elasticity, allowing you to take any form of soil and restrain its subsidence;

- durability and reliability;

- an increase in volume of 14 times with moisture on the material, which allows to achieve uniform coverage of the entire bottom;

- high maintainability - places of damage or punctures can be easily covered with bentonite gel;

- ability to withstand large temperature changes without losing its initial properties;

- environmental friendliness of bentomate.

Like any other material, this material has its drawbacks. First of all, they include a high price, which, however, is more than paid for by durability, and low resistance to chlorides. There is another feature - due to the large increase in volume in conditions of high humidity, bentomats need to provide a load in advance, which helps to keep the material stationary. The best for this case will be a layer of pebbles or stone, a thickness of about 20 cm.

Did you know? According to Feng Shui teachings, the pond on the site attracts material well-being to its owner.

The laying procedure is easy:

- Rolls are rolled out, and the canvases themselves are overlapped (length - 15 cm, width - 30 cm).

- Overlapping spots are sprinkled with bentonite granules to provide waterproofing.

Liquid rubber

Another version of modern waterproofing materials, which, due to its unique properties, has received many positive reviews among consumers. Liquid rubber can be paved with concrete pools and specialized fish ponds.

- Its main advantages include:

- elasticity;

- long term of operation;

- resistance to corrosion and temperature changes;

- environmental friendliness, which means complete safety for the environment.

However, like all new materials manufactured in accordance with modern technologies, such mastic is of high cost. Also, the disadvantages include the need for a special installation device, with which spraying is carried out (industrial spray gun). But there is the possibility of self-application with a roller or brush.

Important! Each subsequent layer must be applied perpendicular to the previous one.

In general, the installation procedure is not very difficult:

- In the case of working with a concrete bottom, liquid rubber is sprayed onto a pre-laid geotextile and then allowed to dry completely (takes 30 to 120 minutes). Due to the solidity and lack of seams, such material does not require any additional treatments and eliminates the formation of leaks. To increase the level of quality and reliability, liquid rubber can be sprayed again (second layer).

- On a soil base, rubber is sprayed in the same way as in the first case, with the exception of the number of required layers - treatment must be repeated 3 times.

Clay

Clay refers to natural methods of laying the insulation of the bottom of a pond or pond. Due to its natural origin, this option is the most cost-effective as well as environmentally friendly. An additional advantage will be the ability to carry out all work independently, even without skills.

The only thing is to trim the bottom with such material is permissible only in garden ponds, in which the depth does not exceed 0.5 m. At the same time, any shapes and design are allowed. Also, this type of insulation will require constant support of the water level, because with seasonal fluctuations the appearance of the reservoir will suffer significantly - the water will become cloudy or will get a dirty yellow hue.

Laying clay insulation has the following sequence:

- First of all, a mortar is prepared on the basis of a mixture of pure clay without inclusions (collected from the lower layers) and water. The final consistency should be pasty.

- The entire surface of the pit is sprinkled with ash or soot from the inside.

- Next, the first clay layer is distributed along the bottom, with a thickness of at least 10 cm, after which the laid mixture is well compacted several times.

- After the first layer begins to dry, apply the next - its thickness should be 30 cm.

- Then a layer of crushed stone of a small fraction (up to 4 cm) follows.

- The entire multilayer mixture is once again well compacted and a thin layer of sand is poured on top (not more than 5 cm).

Liquid glass waterproofing

This material is also called silicate glue and is obtained from an aqueous solution of sodium silicate. Possessing high adhesive abilities, water glass is mandatory for use in ponds with a concrete base for fish farming.

The explanation is simple - concrete chips are extremely dangerous for fish. This material can be applied with a wide brush, with a layer of at least 3 mm. All work begins with the walls of the pond and ends with the bottom.

Waterproofing film

It is the most common waterproofing material for garden water bodies and has sufficient strength and wear resistance for service without loss of initial properties for many years.

- Additionally, such coatings are characterized by the following advantages:

- affordable cost;

- environmental friendliness;

- the possibility of using decorative finishes;

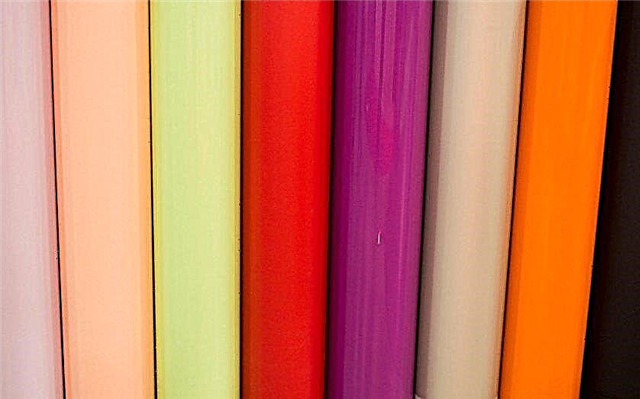

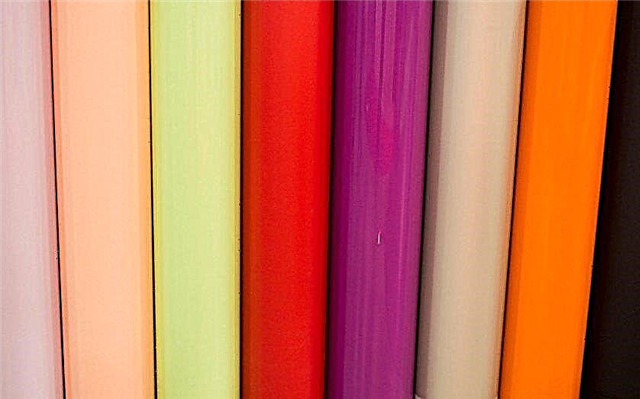

- a variety of colors of the coating;

- simplicity in leaving;

- resistance to mechanical damage and negative chemical effects;

- long term of operation (depending on the chosen type - 10-50 years).

In total there are several main varieties of pond film:

- PVC film (polyvinyl chloride) - a specialized canvas designed for ponds and ponds. A large number of colors allows you to choose the best option, but it is recommended to use dark tones that are as close to natural as possible. The film can initially be sold with decor in the form of a layer of gravel. The thickness of the material varies from 0.5 to 1.5 mm, and the width of the roll - from 2 to 8 m. At the same time, the strips are interconnected with a special glue. The service life of a PVC film (subject to high quality) is more than 10 years.

- EPDM rubber film - It has high technical characteristics (elasticity, strength and resistance to ultraviolet radiation), which makes it very durable (about 50 years). The width of the canvas usually varies between 1.7-7.6 m. It is required to line this material with mandatory overlap, fixing it with a connecting tape. A mandatory procedure is to hide the film at the edges of the pond, in order to avoid quick damage under the influence of the sun and rain.

- Polyethylene film (LDPE-cloth) - compares favorably with its transparency, light, vapor and water resistance. An additional advantage is high strength and elasticity, as well as easy installation, available for independent conduct, even in the absence of special skills.

The technology of laying the film requires a certain sequence:

- The material is laid on top of a prepared sand cushion and geotextile. To cover the film was not difficult, use one of the methods: either spread the entire film in a separate area, mark the center on it, then gently pull it into the middle of the foundation pit of the future pond, or fold the film with an envelope, after making a mark in the center, and then transfer it at the bottom of the pond, placed in the middle and sequentially deploy it in the direction from the middle to the shores.

- At each step of laying, the film is additionally fixed with stones, in order to avoid its shift. In this case, strong tension should be avoided - it is better if the canvas between the tiers will slightly sag.

- Further, the film is equalized and well fixed on the shores with the help of beams, pipes or stones, which can later be decorated with vegetation.

- The last step is to fill the pond with water.

Water should be run under low pressure, which will prevent the film from breaking in places of tension.

Water should be run under low pressure, which will prevent the film from breaking in places of tension.

Is it possible to cover the bottom of the pond with moss

The appearance of the reservoir in the country will primarily depend on the ecosystem created around it and the ongoing support for cleanliness. For this purpose, experienced summer residents often resort to planting the coastal zone and bottom with various plants, including calamus, nymphaeum, cattail, reeds and others.And for the purity of water in the pond, moss sphangum is often used, which either cover the bottom, or are kept in mesh containers at the bottom.

This plant has truly magical properties, the main of which are its antibacterial and disinfectant qualities. They prevent the formation of rotting processes in stagnant water. This makes it possible to avoid frequent and rather time-consuming cleanings, as well as to refuse to use chemical preparations or special equipment.

Waterproofing is a mandatory and important stage in the construction of reservoirs on personal plots. And therefore, despite the chosen method, it is necessary to strictly follow the laying technology and choose only high-quality material. This approach will reduce the number of necessary restoration work to a minimum and not spend a lot of effort and time on keeping the pond in good condition.