Today, traditional wooden hives are gradually becoming a thing of the past, and they are being replaced by lightweight and comfortable structures made of the latest materials such as polystyrene foam (PPS) and polyurethane foam (PPU). The article will discuss the advantages and disadvantages of polystyrene beehives, as well as how to make them yourself.

Did you know? Archaeological research suggests that bees were “domesticated” by humans 5–6 thousand years ago. They were kept in primitive woven from rods or wooden beehives or clay vessels.

Features of polystyrene beehives

Polystyrene is a type of foam. It began to be manufactured in 1928 of the last century in France. In beekeeping, this material began to be used in the 60s of the last century abroad. Domestic beekeepers became acquainted with such hives at about the same time, however, they began to be widely used not so long ago. Some are skeptical of innovation. Others continue to discover new benefits.

Benefits

- Among the advantages of polystyrene beehives should be mentioned:

- light weight, which makes them mobile and simplifies the installation and care of bees;

- strength;

- good thermal insulation characteristics, allowing to maintain a constant temperature inside;

- good sound insulation, due to which the inside is quiet and comfortable for insects;

- interchangeability of parts, which allows repair at any time;

- long term of operation;

- simplicity and ease of use;

- resistance to moisture, decay, cracking;

- lack of need for insulation;

- good ventilation both in warm and in the cold season;

- profitability.

Disadvantages

- Such designs and cons are not without, the main ones are:

- difficulties in cleaning the case of propolis;

- difficulties with disinfection;

- moisture accumulation at the bottom of the hive;

- protection against birds and rodents is required.

How to make a polystyrene beehive on your own?

PPS hives can be purchased ready-made. They are monoblock and collapsible. They consist of a closed or mesh bottom, body, cover, feeder and separation grill. The 10- and 6-frame hives of Dadan, the hive-lounger and others are popular. It is also possible to make homemade bee houses. You can make a polystyrene beehive quickly, but it will take some knowledge and skills. It is important to prepare the necessary materials and tools, as well as clearly follow the manufacturing instructions.

Did you know? A working bee during flight flaps its wings at a frequency of 200 times per minute.

Necessary materials and tools for work

For the manufacture of a 10-frame expanded polystyrene collapsible house for bees on a frame of 145 mm, you will need:

- sheets of extruded PPP with a density of 24–28 kg / m³ (28–32 kg / m³) with dimensions of 1200 × 550 × 50 mm (sold in construction stores, Penoplex, Ursa, and Technonikol are suitable);

- machine for cutting PPP with the simplest device (it can be made independently);

- roulette;

- ruler;

- plastic corners 10 × 10 and 20 × 20 mm;

- wooden blocks under folds;

- jigsaw;

- screwdriver (screwdriver);

- marker;

- electric or office knife;

- aluminum mesh (optimal size 3.5 mm);

- glue;

- water based paint.

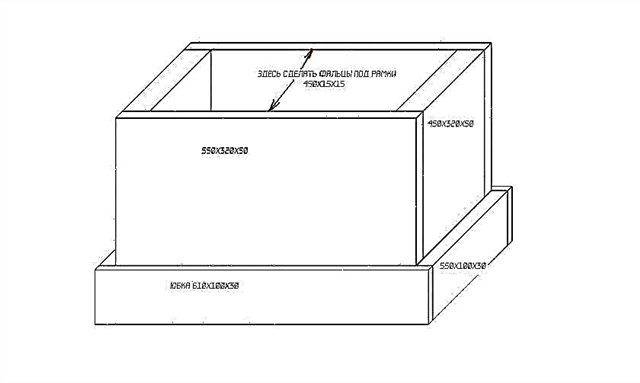

Dimensions and Drawings

For the manufacture of beehives, drawings should be made or ready-made ones should be used, on which the exact dimensions of the body parts: walls, roof and bottom should be indicated.

Housing

The finished housing will have the following dimensions (LxWxH): 540 × 380 × 145 mm.

Bottom and roof

The bottom and the roof have the same dimensions: 540 × 467 mm.

Important! It is necessary to purchase glue, which after drying does not emit harmful substances.

Parts preparation

The next stage is the preparation of blanks for walls, roof and bottom, during which it is necessary to take such steps:

- Peel a layer 4–5 mm thick on one side of the sheets using a cutting machine. It is necessary that the hive is completely smooth from the inside.

- Cut the layer along the length of the sheet to get even and smooth ends.

- Trim the edge of the sheet in width.

- Cut a piece of sheet 540 mm long. It will go to the bottom, cover and 3 walls.

- Cut walls 380 mm wide from already cut pieces.

- Cut out from the remaining pieces folds for the roof and the bottom with a length of 380 mm and a width of 90 mm.

- Cut walls 145 mm high from pieces 380 mm wide and 540 mm long.

- Cut blanks under the bottom and roof with a width of 467 mm and a length of 540 mm.

- Make samples for frames on wall blanks with dimensions of 11 × 11 mm.

- Make a selection for a plastic corner for reinforcing the bottom 20 × 20 mm.

- Make a corner sample on the sidewall 10 × 10 mm, 1.5 mm thick.

- Cut the guides for the roof and under the folds to the bottom of the residues with a width of 24 mm.

Video: do-it-yourself polystyrene beehive, 1 part

Step-by-step assembly instructions

The technology for assembling a house for bees is as follows:

- Mark with a marker 2 windows under the grid on the bottom.

- Make a cut in the center.

- Cut windows with a jigsaw.

- Using an electric or clerical knife, make a frame for the grid.

- Glue plastic corners on the bottom, and the sides of the housings for durability, to protect against mechanical damage. Glue the corners to the ends for the coat hanger under the frame.

- Glue the guides under the folds on the bottom.

- Attach wooden parts to the bottom with self-tapping screws.

- Glue and fix the legs with screws.

- Glue the guides to the roof.

- Leave the parts under the press to dry the glue for 1-2 days.

- Assemble and glue the body. For reliability, fix each seam with 2 self-tapping screws.

- Paint the outside of the case with a water-based emulsion. This will extend the life of the home for bees.

Video: do-it-yourself polystyrene beehive, part 2

Beehive

After the case is completely ready, an aluminum mesh should be installed on the bottom. It is fixed from the inside with small self-tapping screws. Inside the case, corners are attached to which waxed frames are inserted. It is better not to use wooden inserts for frames in such hives, since under the influence of high humidity they will soon become worthless.

Important! When cutting housing parts, it is necessary to strictly adhere to the described dimensions so that there are no gaps. Otherwise, the bees will gnaw at places where the gap will be visible.

Features of use and care

Styrofoam hives are not used as usual. The beekeeper will need to adapt to them. Firstly, there is no ordinary canvas here. Instead, a film is used. Secondly, ventilation is carried out through the notch and openings located in the bottom. Therefore, the upper notch is used only when using dividing grids and during honey collection. Thirdly, thermoregulation occurs differently. In the spring, to preserve heat, it is necessary to close the hole in the bottom, and open the notch by 2–5 cm. Wintering should take place with an open notch and a closed bottom. On top of the frames you need to install a film that will protect from the cold air coming in from above and prevent the draft. So that wind gusts do not demolish a light cover, it is necessary to put a weighting material on it, for example, a brick.

In the spring, to preserve heat, it is necessary to close the hole in the bottom, and open the notch by 2–5 cm. Wintering should take place with an open notch and a closed bottom. On top of the frames you need to install a film that will protect from the cold air coming in from above and prevent the draft. So that wind gusts do not demolish a light cover, it is necessary to put a weighting material on it, for example, a brick.

Did you know? Only working bees leave the hive in search of pollen. When one individual finds a place with a large accumulation of nectar, he informs his "colleagues" about it using a special dance - it moves along a closed curve in the form of an eight, wagging its belly.

Wintering such hives is best done outdoors. They can be easily transported, but be sure to fix them with special mounting straps designed for wandering. It is necessary to protect bee houses from rodents and birds, wearing special casings made of galvanized sheet or plastic bags on them. It is desirable to paint the outer side of the body with water-based paint and restore it as it peels off. There are several more features of polystyrene bee houses.

They consist in prohibited procedures, which include:

- Blowtorch disinfection.

- Impact on the body with a scraper and cord brush.

Beehives are disinfected manually using detergents (soda, soapy solution) or disinfectants (caustic soda, caustic soda, propolis alcohol solution) or mechanical, using a special high-pressure apparatus.

Such novelties in beekeeping as polystyrene foam hives deserve the attention of beekeepers. They have a lot of advantages, easy to use and safe for humans and insects. Such designs can be made with your own hands or you can buy them ready-made.